It is important for us to meet or exceed the expectations of our customers. In line with this, the customer is at the heart of our corporate values. Our activities and internal processes have been designed with this in mind. In order to reach the satisfaction of our customers, we have developed and operate a quality management system that ensures – among other things – the control and traceability of our operational processes, that results in products with impeccable quality. In addition, we continuously measure, evaluate and improve our operational processes.

Welcome to Luckympex Ltd.

High quality manufacturing and professional sheet metal working, project level collaboration and support services.

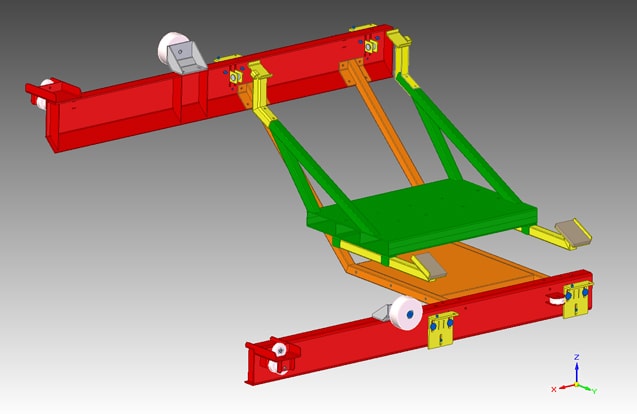

Thanks to our 30 years of experience and the available technologies, our company is suitable for technical design, manufacturing, assembly and on-site installation of machines.

Modern sheet metal fabrication on 2200 square meters.

PERFECT SINERGY OF LASER CUTTING AND BENDING

Complete solutions from design to installation

The right choice for project level cooperation.

Total Quality Management

Our goal is to ensure total customer satisfaction

Our strategic goals

Continuous improvement and cost rationalization

Our long term goals are, economical operation and value-creating activities, which are also proven by the 30-year existence of our company. Luckympex is constantly developing and growing, our range of activities have been rapidly expanding over the years. We are continously improving our technological standards in order to remain competitive.

The management of the company has prepared a strategic plan for long-term, successful operation, has a vision and mission, with formulated strategic goals and operates along them.

Using the Balanced Scorecard (BSc) model, we have assigned metrics to achieve our goals and measure operational performance.

Company history

14000sqm production area, 250 employees, 30 years experience in machine building.

If you have any questions call us

Our colleagues are at your disposal

Customer service:

Tel: +36 82 512 256

Emai: info@luckympex.hu

Technical department

Tel: +36 82 512 257

Procurement

Tel: +36 82 512 016